Nitrogen springs are a type of gas spring that uses nitrogen gas as the compressible medium to provide force and motion in various applications. These springs are commonly used in industries such as automotive, aerospace, and manufacturing for tasks such as lifting, lowering, and counterbalancing loads. In order to ensure the safety and performance of nitrogen springs, there are specific product standards that must be met.

Another key product standard for nitrogen springs is the material quality. Nitrogen springs are often subjected to high levels of stress and pressure, so it is essential that they are made from high-quality materials that can withstand these conditions. Common materials used in the construction of nitrogen springs include stainless steel, carbon steel, and aluminum. These materials must meet certain standards for strength, durability, and corrosion resistance to ensure the longevity and reliability of the spring.

In addition to pressure rating and material quality, nitrogen springs must also meet standards for performance and reliability. This includes factors such as load capacity, stroke length, and operating temperature range. Nitrogen springs must be able to provide the necessary force and motion for their intended application, while also maintaining consistent performance over time. They must also be able to operate effectively in a wide range of environmental conditions, from extreme temperatures to high levels of vibration.

Safety is another critical product standard for nitrogen springs. These springs are often used in applications where failure could result in serious injury or damage, so it is essential that they are designed and manufactured with safety in mind. This includes features such as overload protection, pressure relief valves, and fail-safe mechanisms to prevent accidents and ensure the safe operation of the spring.

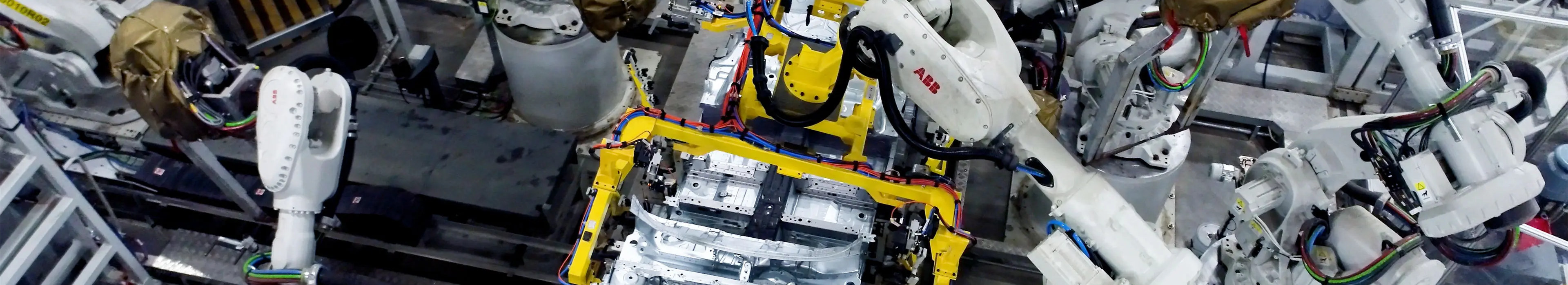

In order to ensure that nitrogen springs meet these product standards, manufacturers must adhere to industry regulations and guidelines. This includes following standards set by organizations such as the International Organization for Standardization (ISO) and the American National Standards Institute (ANSI). These standards outline the requirements for the design, testing, and performance of nitrogen springs, and help to ensure that they meet the highest levels of quality and safety.

Overall, product standards for nitrogen springs are essential for ensuring the safety, performance, and reliability of these important components. By meeting these standards, manufacturers can produce high-quality nitrogen springs that meet the needs of a wide range of industries and applications. Whether used in automotive, aerospace, or manufacturing, nitrogen springs play a crucial role in providing force and motion, and meeting product standards is key to their success.