Non-standard part processing refers to the manufacturing of custom or specialized parts that do not conform to standard industry specifications. These parts are often unique and require special attention to detail in order to meet the specific needs of the customer. In order to successfully process non-standard parts, there are several key application requirements that must be met.

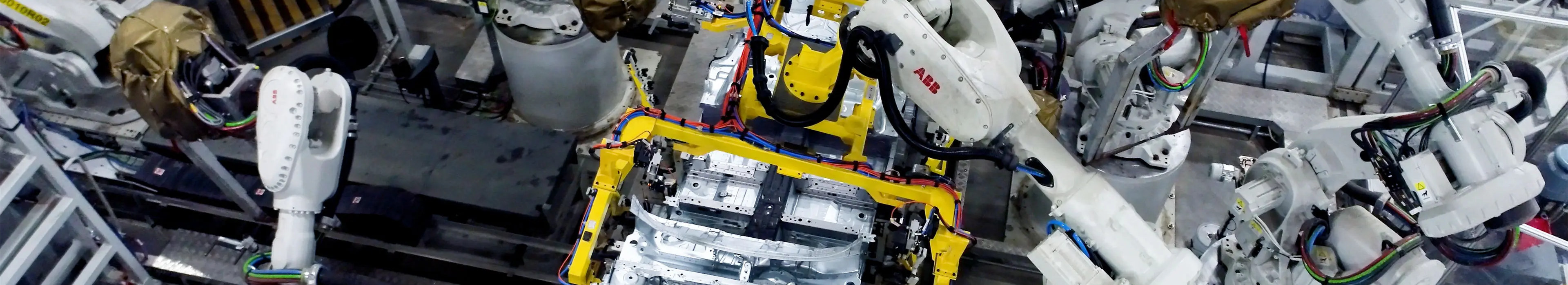

2. Advanced machining capabilities: Non-standard parts often require advanced machining capabilities in order to achieve the desired shape, size, and finish. This may include CNC machining, 3D printing, or other specialized machining techniques. It is important for the manufacturer to have the necessary equipment and expertise to handle these complex processes.

3. Material selection: The choice of material is crucial when processing non-standard parts. The material must be able to withstand the intended use of the part, whether it is for high temperatures, corrosive environments, or other challenging conditions. The manufacturer must have a thorough understanding of different materials and their properties in order to select the most appropriate option.

4. Quality control measures: Quality control is essential when processing non-standard parts to ensure that the final product meets the customer's specifications. This may include regular inspections, testing, and documentation of the manufacturing process. The manufacturer should have a robust quality control system in place to ensure consistency and accuracy in production.

5. Custom tooling and fixturing: Non-standard parts often require custom tooling and fixturing in order to accurately machine the part. This may involve designing and fabricating specialized tools, jigs, or fixtures to hold the part in place during machining. The manufacturer must have the capability to create custom tooling and fixturing to meet the unique requirements of each part.

6. Skilled workforce: Processing non-standard parts requires a skilled and experienced workforce with expertise in machining, materials, and quality control. The manufacturer should have a team of trained professionals who can effectively interpret specifications, operate advanced machinery, and ensure the highest level of quality in production.

7. Communication and collaboration: Effective communication and collaboration between the customer and the manufacturer are essential when processing non-standard parts. The manufacturer must be able to understand the customer's requirements, provide regular updates on the progress of the project, and address any concerns or changes that may arise during production. Clear and open communication is key to ensuring a successful outcome for both parties.

In conclusion, processing non-standard parts requires a combination of advanced machining capabilities, material expertise, quality control measures, custom tooling, skilled workforce, and effective communication. By meeting these application requirements, manufacturers can successfully produce custom parts that meet the unique needs of their customers.